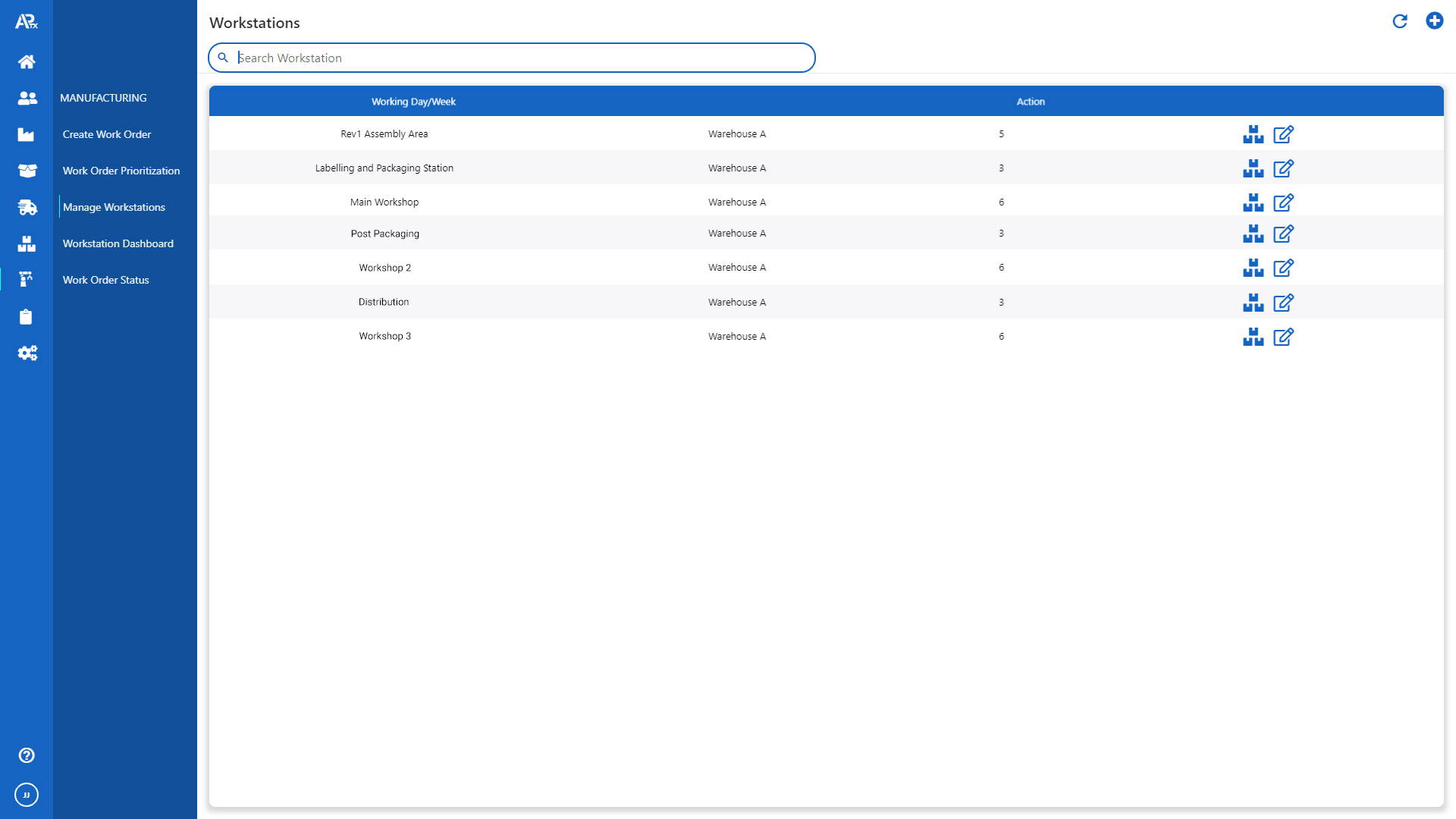

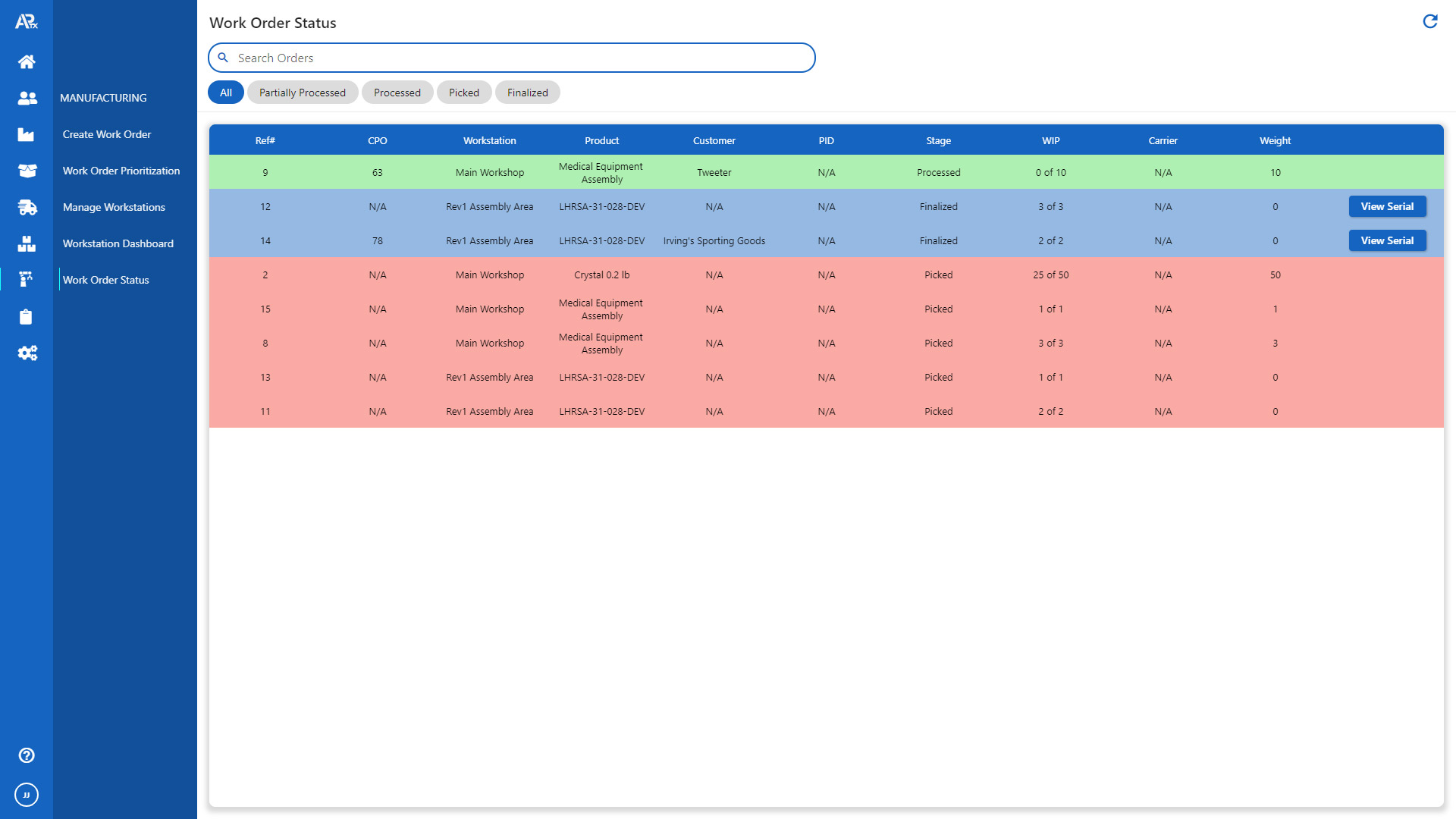

Track the components, quantities and workflow processes so that you can focus on building great products for your customers. This module has been designed to enable a Production Manager to manage, prioritize, and track work orders. Each workstation user can select, assemble, assign serial numbers, upload images and finalize a work order assigned to that workstation.

for FREE and ramp up your business